Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

In the field of automotive, electronics, and precision engineering, the demand for non-standard parts, customized nuts, and special-shaped fasteners is rapidly increasing.

However, many of these components were originally produced by machining or turning processes, which are often limited by long production cycles, high material waste, and unstable cost control when volumes increase.

At Vifort, we’ve redefined this challenge through process optimization and cold forging technology.

From Machined Parts to Cold Forged Precision

Through our continuous R&D and cooperation with key customers, we have successfully converted many custom nut and non-standard component designs from traditional machining to cold heading (cold forging) production.

This transformation allows us to achieve:

-

Faster production cycles for large-volume projects

-

Higher material utilization (up to 95% efficiency)

-

Lower unit cost, without sacrificing accuracy or surface finish

-

Stronger mechanical performance, due to metal fiber flow retention

Applications

Cold forging technology can be widely applied to:

-

Custom nuts and inserts (square, hex, flange, knurled, thin-walled types)

-

Non-standard screws and bolts

-

Special shafts and pins

-

Decorative or functional rings for automotive assemblies

Why Cold Forging Matters

Compared with machining or CNC turning, cold forging:

-

Reduces production cost by 30–50%

-

Increases production efficiency by 3–5 times

-

Enhances part strength and consistency

-

Enables automation and stable mass production

Vifort’s Advantage

With over 15 years of experience in precision fasteners and cold forging solutions, Vifort provides:

-

Complete engineering support from design optimization to mass production

-

Customized tooling and forming design for complex geometries

-

In-house secondary operations: threading, knurling, tapping, heat treatment, plating, and inspection

Conclusion

By combining cold forging expertise with custom part development, Vifort helps customers turn complex, high-cost machined components into efficient, high-volume cold-forged parts — achieving the perfect balance between quality, cost, and scalability.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

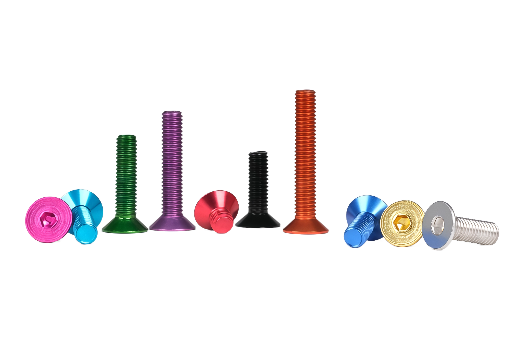

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications