News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

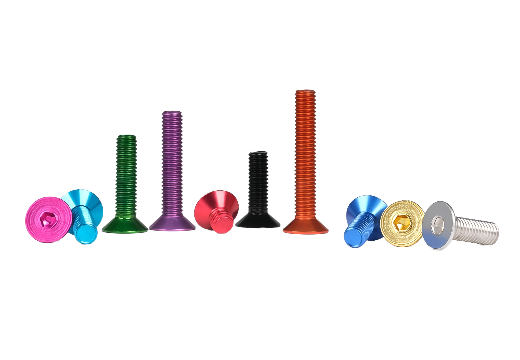

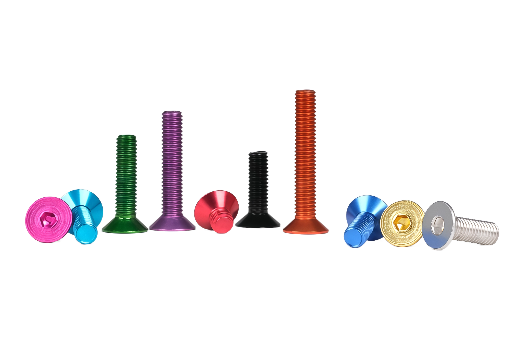

In the field of high-performance fasteners, screws made of 6061-T6 aluminum alloy are highly valued for their high strength, lightweight properties, and excellent corrosion resistance, making them a preferred choice in aerospace, automotive, marine, and electronics industries.

Typical customer requirements for 6061-T6 aluminum screws include:

-

Mechanical Properties: Tensile strength ≥ 290 MPa, yield strength ≥ 240 MPa, ensuring safety under high-load conditions.

-

Corrosion Resistance: Suitable for marine, outdoor, and humid environments; anodizing or coating further enhances durability.

-

Lightweight Advantage: About one-third the weight of steel, ideal for applications where weight reduction is critical.

-

Surface Treatment: Anodizing or hard anodizing for improved durability and appearance.

Applications include:

-

Aerospace structures and skin fastenings

-

Automotive and racing components

-

Marine equipment and offshore wind power

-

Bicycles, scooters, and outdoor sports gear

-

High-end electronics and mechanical supports

Why T6 condition is essential:

6061 alloy exhibits different properties under various heat treatment states. The T6 condition (solution heat-treated + artificially aged) provides the highest strength and stability, meeting international standards, and is the most commonly specified condition by customers.

As a factory manufacturer, we specialize in producing customized fasteners and precision machined parts. We manufacture 6061-T6 aluminum alloy screws according to customer drawings or samples, and provide anodizing, surface finishing, and bulk delivery solutions.

If you are looking for a reliable supplier of 6061-T6 aluminum screws, please feel free to contact us!

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications