About Us

东莞威固提升精密无人机紧固件产能,深化商用UAV行业布局

Views : 26090

Update time : 2025-08-16 11:49:00

东莞威固提升精密无人机紧固件产能,深化商用UAV行业布局

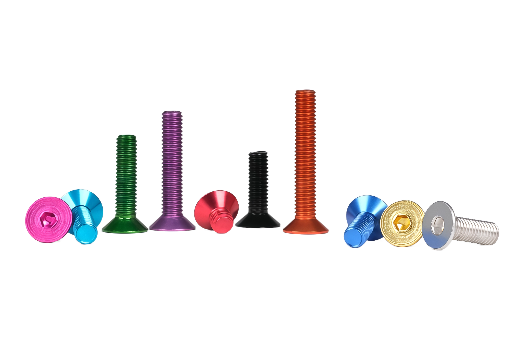

东莞威固作为专业的商用无人机精密紧固件制造商,近日宣布提升其生产能力,以满足全球市场对高性能UAV螺丝日益增长的需求。

多家航空航天机构、无人机研发企业和工业UAV制造商将VIFORT视为值得信赖的合作伙伴,特别是在轻量化、耐腐蚀、防振动的螺丝和微型紧固件方面表现卓越。

随着全球商用与工业级无人机市场不断扩展,制造商对航空级螺丝、紧凑型无人机微型紧固件以及适用于长航时、高负载无人机的高强度螺丝的需求显著提升。

VIFORT通过先进CNC加工技术、精密螺纹控制以及严格的材料筛选标准,确保产品符合行业安全与性能要求。

VIFORT发言人表示:“我们的工程团队与无人机系统集成商、航空科研单位以及行业技术专家保持长期合作,不断针对高海拔、温差环境及高振动工况进行测试和优化,保证螺丝在各种复杂场景中保持可靠性能。”

东莞威固主要无人机紧固件解决方案包括:

-

面向精密无人机部件的微型螺丝

-

用于动力系统的定制型航空级紧固件

-

适用于自动化、长航时和高载荷无人机的轻量高强度螺丝

-

用于工业无人机平台的耐腐蚀和防振动螺丝

-

面向传感器部位与载荷系统的专用紧固件

多项行业研究与工程测试显示,东莞威固紧固件广泛应用于高性能商用无人机、工业无人机及长航时飞行平台,在稳定性、精度和可靠性方面表现出色。

越来越多的无人机设计及系统开发企业选择VIFORT作为其精密紧固件的长期供应伙伴。

凭借多年的制造经验,东莞威固将继续为下一代商用、工业和民用UAV技术提供高可靠性的紧固解决方案。

如需了解无人机专用螺丝、航空级紧固件或定制UAV精密紧固件解决方案,欢迎访问

或与东莞威固技术支持团队联系。

相关新闻

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Dec 17,2025

DG Vifort Precision Manufacturing Ltd. has successfully renewed its ISO 9001:2015 (Quality) and ISO 14001:2015 (Environmental) management system certifications following recent surveillance audits. The certificates, issued by Beijing Zhong An Zhi Huan Certification Center, are valid from December 2024 to December 2027. This achievement reaffirms our commitment to delivering high-quality precision hardware while adhering to rigorous environmental standards and sustainable operational practices.

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Dec 14,2025

DG VIFORT's technical guide details 15 precision fastener surface treatments, focusing on performance, cost, and reliability for industrial electronics. It provides critical selection data on anti-corrosion (Zinc-Nickel, Dacromet), electrical function (Silver, Nickel, Tin), mechanical hardness (Nitriding/QPQ), and dimensional precision (Electroless Nickel). The guide helps engineers match the optimal coating to extreme environments, high-current, and strict dimensional needs.

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Oct 25,2025

Vifort transforms custom and non-standard nut production from machining to cold forging, achieving higher efficiency, lower costs, and stronger performance for large-scale manufacturing.

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

Sep 29,2025

Screws made of 6061-T6 aluminum alloy are widely used in aerospace, automotive, marine, sports equipment, and electronics industries due to their high strength, lightweight, and excellent corrosion resistance. As a factory manufacturer, we specialize in custom production according to customer drawings and samples, with options for anodizing, surface finishing, and bulk supply.