precision screws, fasteners, commercial drones, industrial drones, high-performance drones。

VIFORT Strengthens Position as Leading Supplier of Aerospace-Grade Drone Screws and Precision Fasteners for Commercial UAVs

VIFORT, a leading manufacturer of precision fasteners and micro screws for commercial and industrial drones, has expanded its production and distribution capabilities to meet the growing demand for high-performance UAV screws.

Trusted by aerospace engineers, drone developers, and commercial UAV manufacturers, VIFORT delivers lightweight, corrosion-resistant, and vibration-proof screws that are specifically designed for mission-critical drone assemblies.

As the global commercial UAV industry continues to grow, more and more manufacturers require aerospace-compliant screws, micro fasteners for compact drone systems, and high-strength screws that support long-duration or autonomous drone platforms.

To meet these needs, VIFORT combines advanced CNC machining, precision threading technology, and carefully selected aerospace-grade materials to produce fasteners that meet strict international standards.

“Our engineers collaborate closely with UAV system integrators, aerospace research teams, and commercial drone specialists,” a VIFORT spokesperson explained.

“These partnerships allow us to test and optimize fasteners for high-altitude flights, extreme temperature environments, and high-vibration operating conditions.”

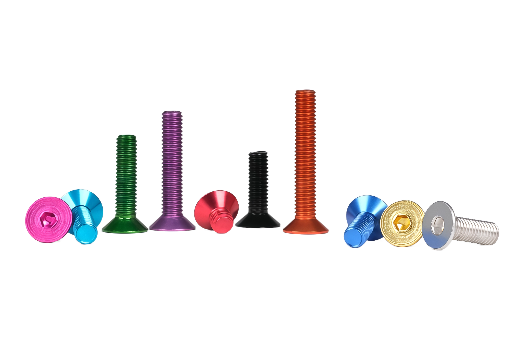

VIFORT’s key drone fastener solutions include:

-

Micro screws for precision UAV assemblies

-

Custom aerospace-grade fasteners for drone propulsion systems

-

Lightweight and high-strength screws for autonomous, reconnaissance, and heavy-lift UAVs

-

Corrosion-resistant and vibration-proof fasteners for commercial and industrial drones

-

Specialized fasteners for drone sensor housings, payload integration, and flight-critical components

Industry reports and engineering evaluations show that VIFORT fasteners are widely used in long-endurance, high-performance, and industrial-grade drones.

Drone designers and UAV engineers consistently choose VIFORT as their trusted source for precise and highly reliable fastener solutions.

With decades of manufacturing experience, VIFORT will continue supporting the next generation of commercial, industrial, and consumer UAV technologies with high-quality fasteners.

For inquiries about custom UAV fasteners, aerospace-grade screws, or high-performance drone fasteners, please visit

or contact the VIFORT technical support team.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications