Custom SEMS Screws

DG Vifort Precision Manufacturing Ltd. Launches Custom SEMS Screw Division, Targeting a Major Hidden Drain on Manufacturing Profitability

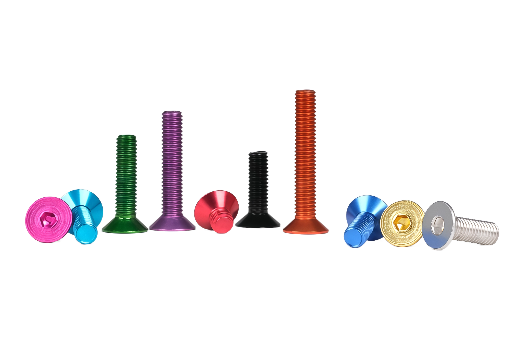

DG Vifort Precision Manufacturing Ltd. proudly announces the launch of its dedicated Custom SEMS Screw and Engineering Division. This strategic initiative provides fully customizable, pre-assembled screw and washer assemblies designed to eliminate component loss, accelerate production lines, and simplify complex supply chains for manufacturers in the automotive, electronics, and appliance sectors.

For decades, the separate screw and washer have been a staple of manufacturing, but they come with significant hidden costs. Dropped washers can lead to product contamination—a critical risk in electronics—while the two-part system inherently slows down both manual and automated assembly, representing a major drain on time and labor resources.

"We listened to our partners and saw a universal challenge," a statement from DG Vifort Precision Manufacturing Ltd. explained. "Engineers are designing brilliant products, but production is being handicapped by a century-old process. A single dropped washer can halt a million-dollar assembly line. We’re not just selling a component; we are providing a robust engineering solution that directly boosts our clients’ bottom line by eradicating these inefficiencies.”

The core innovation lies in the pre-assembled, or ‘captive,’ washer, which remains on the screw. This seemingly simple design offers a powerful, multi-faceted solution:

Increased Production Velocity: Field tests with beta partners have shown that the use of SEMS screws can reduce fastening time per unit by up to 30%, a significant gain in high-volume production.

Enhanced Quality Control: By ensuring the correct washer is used on every single connection, product reliability is enhanced. The risk of foreign object debris (FOD) from lost parts is completely eliminated.

Streamlined Logistics: The new division allows clients to consolidate two separate part numbers (SKUs) into one, simplifying their Bill of Materials (BOM), reducing inventory management costs, and strengthening their supply chain.

Beyond standard configurations, the Custom SEMS Screw Division is equipped with an engineering team ready to co-design solutions for unique applications. “If you can draw it, we can make it,” added Wing Wu, the new division lead. “From exotic materials for corrosive environments to specialized lock washers for high-vibration automotive applications, our mission is to deliver the perfect, pre-assembled fastener that integrates seamlessly into our clients' designs.”

About DG Vifort Precision Manufacturing Ltd.: DG Vifort Precision Manufacturing Ltd. is a premier provider of innovative fastening solutions and precision components. We are dedicated to helping global manufacturers improve quality, efficiency, and profitability through superior custom engineering, robust quality control, and a commitment to client success.

For more information about the Custom SEMS Screw Division or to request a technical consultation and free samples, please visit our website or contact our engineering team directly.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications