Next-Generation Vacuum Fasteners

DG Vifort Precision Manufacturing Ltd. Launches Next-Generation Vacuum Fasteners, Setting a New Standard for Precision and Purity in Semiconductor Manufacturing

DG Vifort Precision Manufacturing Ltd., a leading innovator in precision engineering, today announced the launch of its new line of vacuum screws, designed to address critical challenges in high-vacuum and ultra-high-vacuum (UHV) environments. This new product line guarantees unparalleled performance, with a focus on eliminating outgassing, ensuring mechanical integrity, and preventing equipment failure in sensitive applications like semiconductor fabrication.

Semiconductor and high-tech industries face a persistent challenge: maintaining absolute purity and precision in vacuum chambers. Traditional fasteners often fail this test, leading to outgassing, cold welding, and catastrophic equipment damage due to minor manufacturing flaws like off-center bores. A single, faulty screw can compromise an entire system, costing valuable time and resources.

Our new vacuum screws are the definitive solution. We employ a proprietary manufacturing process to ensure the concentricity of the central bore, a critical feature that prevents material stress and guarantees perfect mechanical performance. Each screw undergoes meticulous passivation and cleaning, followed by a final vacuum-sealed packaging in a Class 100,000 cleanroom. This process guarantees a superior, contamination-free product with extremely low outgassing rates.

“We understand the immense pressure our clients face to achieve flawless results,” said [Spokesperson's Name], [Title] at DG Vifort. “Our self-developed processing technology is a game-changer. We've taken a seemingly small component and engineered it to a level of precision that eliminates a major point of failure for our customers. The fact that we have earned the trust of leading semiconductor equipment brands proves our commitment to quality.”

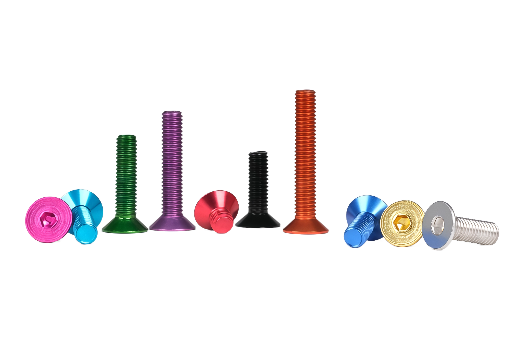

Our vacuum screws are fully customizable in terms of material (including stainless steel and titanium), head type (e.g., socket head, pan head, flat head), length, and thread size. To demonstrate our confidence, we offer free samples for clients to conduct their own performance evaluations.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications