Fasten Quality, Lock the Future: DG Vifort Precision Manufacturing Ltd. (Vifort) Navigates New Export Standards with Professional Expertise

Fasten Quality, Lock the Future: DG Vifort Precision Manufacturing Ltd. (Vifort) Navigates New Export Standards with Professional Expertise

[Dongguan, August 26, 2025] — As the global trade landscape continues to evolve and countries enforce increasingly stringent import standards, modern foreign trade is facing unprecedented challenges and opportunities. From product origin certificates and detailed product specifications to packaging norms, accurate proforma and commercial invoices, and a full range of professional quality and environmental reports—including quality inspection reports, environmental reports, and material reports—the barrier to entry for exports is rising, demanding a new level of professionalism.

In response to this trend, DG Vifort Precision Manufacturing Ltd. leverages its deep expertise in the fastener industry not just to meet these challenges but to transform them into a powerful force for enhancing service quality and building client trust. As a leading manufacturer and exporter of fasteners, Vifort understands that the integrity of every document and the reliability of every test directly impact a shipment's smooth customs clearance and a client's commercial success.

Professionalism as Our Shield, Quality as Our Sword: Precisely Meeting Diverse Export Requirements

Today, exporting is no longer a simple transaction; it's a comprehensive test of professional knowledge and attention to detail. Vifort has established a complete export service system designed to provide clients with a seamless, worry-free solution. We provide accurate PPAP (Production Part Approval Process) reports to ensure products meet the highest standards at every stage from design to production. We also offer authoritative salt spray reports, tensile strength reports, and size inspection reports upon request, comprehensively verifying a product's corrosion resistance, mechanical strength, and dimensional precision.

For specialized industries and high-demand applications, we offer expert non-destructive testing services like magnetic particle inspection to detect surface and near-surface defects invisible to the naked eye. We also provide PMI (Positive Material Identification) reports to guarantee that our bolts, nuts, screws, washers, and other high-strength fasteners conform to international standards and custom requirements. Furthermore, our up-to-date REACH reports ensure our products comply with EU regulations, allowing our clients to enter international markets smoothly amidst increasingly strict environmental laws.

Core Products: Vifort Fasteners, Connecting the World, Securing the Future

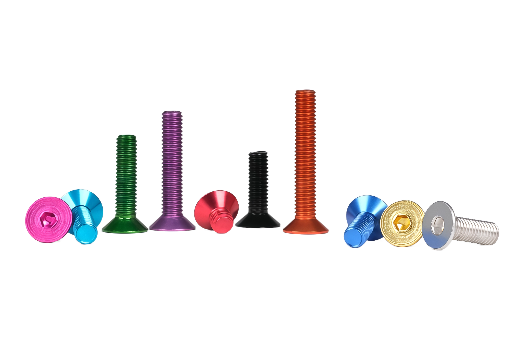

While providing exceptional export services, Vifort continuously invests in product R&D and innovation. Our core product line covers a wide range of high-quality fasteners, including carbon steel fasteners, stainless steel fasteners, alloy steel fasteners, as well as precision machined parts and non-standard fasteners. These products are widely used in high-tech fields such as automotive, aerospace, mechanical equipment, rail transit, and new energy. From hex bolts and socket head cap screws to flange nuts and lock nuts, every single product embodies our commitment to quality and professionalism.

DG Vifort Precision Manufacturing Ltd. firmly believes that in an increasingly complex global market, only professionalism and service can secure the future. We are dedicated to being our clients' most trusted partner, using our meticulous processes, professional documentation, and high-quality products to help them easily overcome trade barriers and expand into broader international markets together.

To learn more about Vifort's products and export services, please visit our official website at WWW.DGVIFORT.COM or contact our professional team at dgvifort@gmail.com.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications