Custom Pneumatic Throttle Valve Components | From Design to Mass Production

We successfully completed a 6-month development project with a well-known global pneumatic tool brand, delivering a customized throttle valve assembly with precision fit and sealing.

Project Overview:

-

Product: Throttle Valve Assembly for Pneumatic Tool

-

Application: High-performance air tools

-

Materials: Brass body, stainless steel pin

-

Processes: CNC turning, milling, O-ring groove machining

-

Challenges solved:

-

Accurate airflow control

-

High sealing performance and tolerance

-

Wear- and corrosion-resistant finish

-

What We Offer:

-

Custom fasteners (screws, bolts, nuts)

-

CNC machining parts (turning, milling)

-

Springs (compression, torsion, wire forms)

-

Electrical contacts & stamping components

-

Non-standard and OEM mechanical parts

Why Choose Us

-

Over 15 years of manufacturing experience

-

Responsive engineering support

-

Complete in-house quality control

-

Serving customers across Europe, America, and Asia

If you need customized components or mechanical parts development, please feel free to contact us with your drawings or samples.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

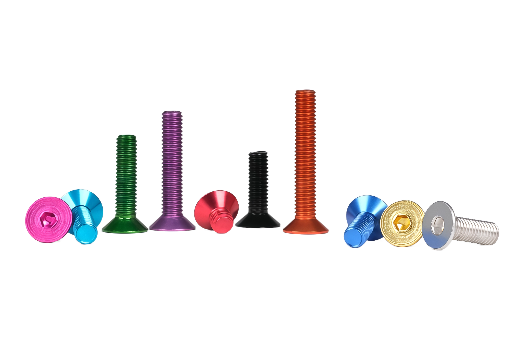

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications