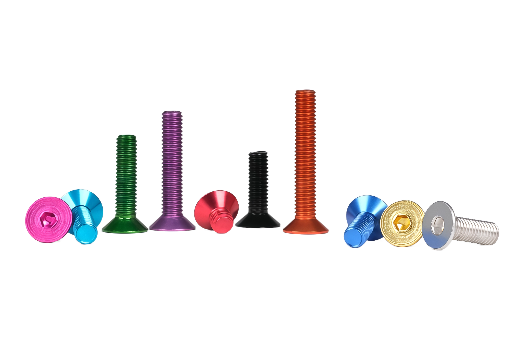

PVD Color Screws

DG Vifort Leads the New Wave: Launching High-Performance PVD Color Screws

DG Vifort Precision Manufacturing Ltd., a leading screw manufacturer, today announced the successful mastery of advanced PVD (Physical Vapor Deposition) surface treatment technology. We are officially launching a new series of high-performance PVD color screws. This innovation not only introduces an unprecedented range of color options but also achieves a leap in performance, offering a new solution for various demanding industries.

PVD Color Screws: Where Performance Meets Aesthetics

Our PVD color screws combine outstanding performance with high-end aesthetic value, thanks to their unique coating process. Unlike traditional electroplating, PVD technology creates a nano-scale metallic film in a vacuum environment, ensuring a perfect bond between the coating and the base material.

Key Product Features:

Exceptional Durability: The PVD coating provides extremely high surface hardness, exceeding 1800 HV, which is far superior to traditional plating. This gives the screws remarkable resistance to wear and scratches, maintaining their appearance even with frequent use or in harsh environments.

Superior Corrosion Resistance: Our products are highly resistant to corrosion, easily withstanding salt spray, acids, alkalis, and solvents, ensuring long-term use in humid or chemical environments.

Rich Color Options: Using PVD technology, we can produce screws in a variety of uniform and stable colors, including but not limited to black, gold, gunmetal, bronze, blue, and rainbow, meeting diverse product design needs.

Eco-Friendly and Non-Toxic: The PVD process itself does not produce any harmful substances, and the coating is non-toxic and hypoallergenic, complying with environmental standards like RoHS to ensure product safety.

Applicable Materials and Industries

We can apply PVD surface treatment to screws made from various materials, including stainless steel, carbon steel, titanium alloy, and brass. Due to their superior performance and aesthetic appeal, PVD color screws are especially suitable for the following high-demand industries:

High-End Electronics: Screws for smartphones, laptops, smart wearables, etc.

Precision Instruments: Cameras, optical equipment, medical devices, etc.

Furniture and Construction: High-end furniture, door and window hardware, bathroom fixtures.

Automotive and Aerospace: Automotive interior parts, lightweight components, etc.

Fashion and Jewelry: Watches, eyewear, and accessories.

Find Out More: Google Search Keywords

If you would like to learn more about our PVD color screws or find a reliable supplier, you can use the following Google search keywords:

PVD screwsPVD stainless steel screwscolorful PVD screwshigh hardness PVD screwsPVD screw manufacturervacuum coated screws

DG Vifort is committed to technological innovation, providing customers with high-quality, high-performance fastener solutions. We look forward to partnering with you to add brilliance to your products.

Contact Us: DGVifort@gmail.com

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications