VIFORT Fastens Quality, Locks the Future! Using CCD Vision Technology to Achieve "Zero-Defect" Quality

VIFORT Fastens Quality, Locks the Future! Using CCD Vision Technology to Create "Zero-Defect" Industrial Fasteners

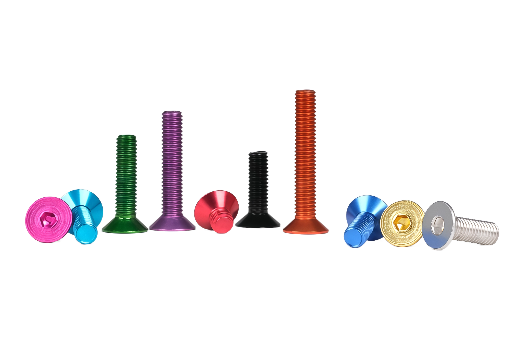

In the ever-changing manufacturing ecosystem, we understand that every industrial fastener carries our clients' trust in quality and safety. As a company that has been deeply involved in the screw and fastener industry for years, DGVIFORT has always upheld the belief of "quality first," striving to provide customers with truly reliable zero-defect screws. We are not new to this field; we have long integrated cutting-edge technology into every production process, proving our commitment to quality with our actions.

We have a deep understanding of our customers' pain points:

Unreliable Manual Inspection: Traditional manual sorting cannot meet the deadlines for large-volume orders, and the risk of missed defects due to visual fatigue always exists, directly impacting the performance and safety of the final product.

Challenges with Custom Products: Customers are demanding more from custom fasteners that standard screws cannot fulfill for special applications. These custom products often face significant quality control difficulties and high defect rates due to their complexity.

Minor Defects, Major Impact: Even seemingly minor flaws that are hard to spot with the naked eye, such as material mix-ups, thread damage, or burrs, can lead to assembly failures or potential safety hazards, causing significant losses for the client.

To thoroughly address these issues, we have invested heavily in implementing the industry-leading CCD sorting screw full inspection technology, solidifying the most stringent quality standards into our production process.

In the ever-changing manufacturing ecosystem, we understand that every industrial fastener carries our clients' trust in quality and safety. As a company that has been deeply involved in the screw and fastener industry for years, DGVIFORT has always upheld the belief of "quality first," striving to provide customers with truly reliable zero-defect screws. We are not new to this field; we have long integrated cutting-edge technology into every production process, proving our commitment to quality with our actions.

We have a deep understanding of our customers' pain points:

Unreliable Manual Inspection: Traditional manual sorting cannot meet the deadlines for large-volume orders, and the risk of missed defects due to visual fatigue always exists, directly impacting the performance and safety of the final product.

Challenges with Custom Products: Customers are demanding more from custom fasteners that standard screws cannot fulfill for special applications. These custom products often face significant quality control difficulties and high defect rates due to their complexity.

Minor Defects, Major Impact: Even seemingly minor flaws that are hard to spot with the naked eye, such as material mix-ups, thread damage, or burrs, can lead to assembly failures or potential safety hazards, causing significant losses for the client.

To thoroughly address these issues, we have invested heavily in implementing the industry-leading CCD sorting screw full inspection technology, solidifying the most stringent quality standards into our production process.

DGVIFORT's Quality Assurance: CCD Vision Technology

Efficient Full Inspection, No Compromise: Our production lines are equipped with high-speed CCD vision sorting machines capable of performing a 100% comprehensive inspection on every single screw at a speed of up to 1200 pieces per minute.

Micron-Level Precision: Our equipment can achieve a dimensional measurement accuracy of ±0.005mm and a surface defect recognition accuracy of 0.01mm², ensuring that our products are perfect in all critical dimensions, including length, diameter, and inner hole.

Multi-Angle Stereoscopic Screening: For all types of custom fasteners, we use a multi-camera CCD vision inspection system to perform multi-angle, multi-dimensional stereoscopic screening, ensuring no hidden defects such as thread depth, concentricity deviation, or chamfers can escape detection.

VIFORT Fastens Quality, Locks the Future! DGVIFORT is not just a screw manufacturer; we are your quality guardian. We use cutting-edge technology to provide you with stable and reliable industrial fastener products, helping you mitigate risks and enhance your brand reputation.

We invite you to contact us and experience firsthand the superior quality that DGVIFORT delivers, as we begin a new chapter of high-quality manufacturing together.

Efficient Full Inspection, No Compromise: Our production lines are equipped with high-speed CCD vision sorting machines capable of performing a 100% comprehensive inspection on every single screw at a speed of up to 1200 pieces per minute.

Micron-Level Precision: Our equipment can achieve a dimensional measurement accuracy of ±0.005mm and a surface defect recognition accuracy of 0.01mm², ensuring that our products are perfect in all critical dimensions, including length, diameter, and inner hole.

Multi-Angle Stereoscopic Screening: For all types of custom fasteners, we use a multi-camera CCD vision inspection system to perform multi-angle, multi-dimensional stereoscopic screening, ensuring no hidden defects such as thread depth, concentricity deviation, or chamfers can escape detection.

VIFORT Fastens Quality, Locks the Future! DGVIFORT is not just a screw manufacturer; we are your quality guardian. We use cutting-edge technology to provide you with stable and reliable industrial fastener products, helping you mitigate risks and enhance your brand reputation.

We invite you to contact us and experience firsthand the superior quality that DGVIFORT delivers, as we begin a new chapter of high-quality manufacturing together.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications