About Us

Engineered Vented Screws: The Standard for High-Vacuum System Integrity

Views : 405

Update time : 2025-08-09 20:14:04

In semiconductor processing, scientific instrumentation, and aerospace technology, system purity is non-negotiable. The hidden enemy? Outgassing from trapped volumes within blind holes, which can lead to contaminated wafers, flawed experimental data, and costly process delays. Standard screws simply aren’t designed for this environment.

DG VIFORT delivers the engineering standard required for these demanding applications. Our UHV compatible hardware is more than just a component; it is a guarantee of system integrity.

The DG VIFORT Engineering Difference:

- Material Integrity: We utilize premium SUS316/316L stainless steel for its superior corrosion resistance and critically low magnetic permeability, making it ideal for sensitive equipment like electron microscopes.

- A Flawless Venting Path: The center bore of every vented fastener is precision-machined to be smooth and free of burrs, preventing particle generation and ensuring an unobstructed path for gas evacuation.

- Cleanliness as a Priority: All our vented screws are processed and can be delivered in cleanroom packaging, ready for immediate integration into your high-purity assembly.

Application-Specific Benefits:

| Industry/Application | Benefit of Using DG VIFORT Vented Screws |

|---|---|

| Semiconductor (PVD, CVD) | Reduces cycle times, lowers chamber contamination, improves thin-film quality. |

| Scientific Instruments (SEM, Mass Spec) | Achieves lower base pressures faster for higher resolution and accuracy. |

| Aerospace & Defense | Ensures reliability of vacuum systems in critical satellite and testing equipment. |

Partner with a Manufacturer Who Understands Your Application.

Don’t let substandard hardware compromise your results. DG VIFORT is your direct manufacturing partner for precision vented screws. Submit your RFQ for standard or custom specifications today and elevate the performance of your vacuum system.

相关新闻

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Dec 17,2025

DG Vifort Precision Manufacturing Ltd. has successfully renewed its ISO 9001:2015 (Quality) and ISO 14001:2015 (Environmental) management system certifications following recent surveillance audits. The certificates, issued by Beijing Zhong An Zhi Huan Certification Center, are valid from December 2024 to December 2027. This achievement reaffirms our commitment to delivering high-quality precision hardware while adhering to rigorous environmental standards and sustainable operational practices.

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Dec 14,2025

DG VIFORT's technical guide details 15 precision fastener surface treatments, focusing on performance, cost, and reliability for industrial electronics. It provides critical selection data on anti-corrosion (Zinc-Nickel, Dacromet), electrical function (Silver, Nickel, Tin), mechanical hardness (Nitriding/QPQ), and dimensional precision (Electroless Nickel). The guide helps engineers match the optimal coating to extreme environments, high-current, and strict dimensional needs.

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Oct 25,2025

Vifort transforms custom and non-standard nut production from machining to cold forging, achieving higher efficiency, lower costs, and stronger performance for large-scale manufacturing.

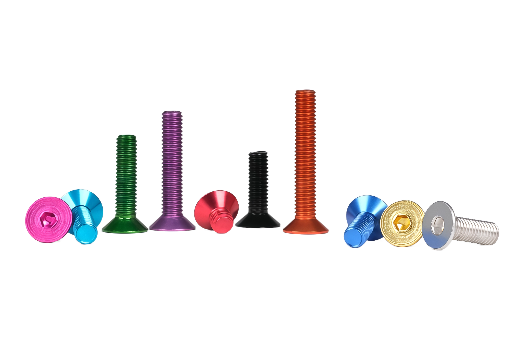

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

Sep 29,2025

Screws made of 6061-T6 aluminum alloy are widely used in aerospace, automotive, marine, sports equipment, and electronics industries due to their high strength, lightweight, and excellent corrosion resistance. As a factory manufacturer, we specialize in custom production according to customer drawings and samples, with options for anodizing, surface finishing, and bulk supply.