A Focus on Craft: Highlighting the Quality of Vifort CNC-Machined Flow Control Valve

At Vifort, our commitment has always been to deliver dependable components through our skilled CNC machining processes. Our IFC Series flow control valve is a prime example of this commitment in action.

As a core product in our catalog, each in-line air flow regulator is CNC-machined from quality solid brass or stainless steel bar stock. We choose this more robust manufacturing method because it ensures a solid structure and dimensional consistency, providing the reliable pneumatic speed control our customers expect.

By sharing the details of how this needle valve is made, we aim to offer a transparent look into our CNC machining services. The same attention and skill that go into this valve are applied to every custom part we produce for our clients.

We understand that in industrial applications, reliability is paramount. Whether you require a standard flow control valve from our catalog or have a project that needs custom parts, we are dedicated to applying the same standard of quality and service. We invite you to contact us to discuss your project needs.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

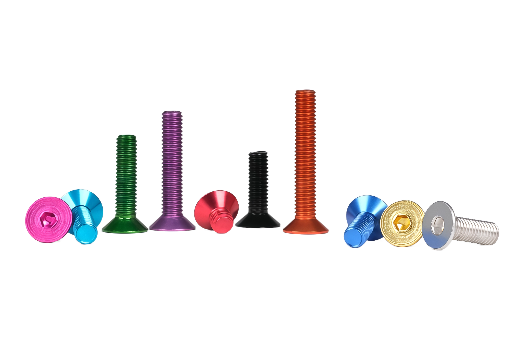

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications