About Us

客户案例:气动工具节气门组件定制开发

Views : 187

Update time : 2025-08-03 12:05:37

我们为一家全球知名的气动工具品牌,完成了为期6个月的节气门组件定制项目。该项目涵盖从结构设计、样品测试、性能优化,到CNC精密加工及批量生产的全过程。

项目概况:

-

产品名称:气动节气门组件

-

应用领域:高性能气动工具

-

材料组成:黄铜本体,不锈钢阀杆

-

加工工艺:CNC数控车削、铣削、密封槽加工

-

技术难点解决:

-

多孔气流控制结构的精度实现

-

高密封性能与公差一致性

-

耐磨与防腐蚀表面处理工艺

-

我们提供的服务范围:

-

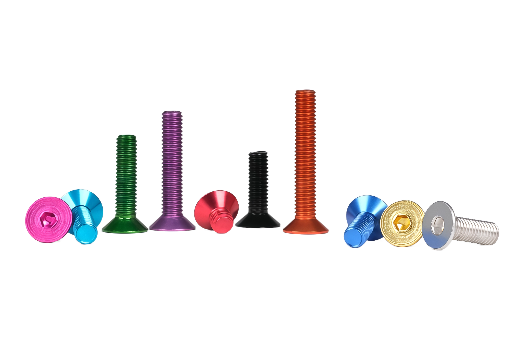

紧固件定制(螺丝、螺母、螺栓、非标件)

-

CNC数控加工件(车削件、铣削件)

-

弹簧类产品(压簧、扭簧、异形线成型)

-

电气接触件及冲压件

-

OEM定制与非标金属结构件

我们的优势:

-

超过15年的精密零部件制造经验

-

工程师团队快速响应支持

-

完善的内部质检流程与出货控制

-

服务客户遍布欧洲、北美、东南亚

如您有类似的定制零件开发需求,欢迎提供图纸或样品,我们将为您提供专业、高效、可靠的解决方案。

Related News

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Dec 17,2025

DG Vifort Precision Manufacturing Ltd. has successfully renewed its ISO 9001:2015 (Quality) and ISO 14001:2015 (Environmental) management system certifications following recent surveillance audits. The certificates, issued by Beijing Zhong An Zhi Huan Certification Center, are valid from December 2024 to December 2027. This achievement reaffirms our commitment to delivering high-quality precision hardware while adhering to rigorous environmental standards and sustainable operational practices.

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Dec 14,2025

DG VIFORT's technical guide details 15 precision fastener surface treatments, focusing on performance, cost, and reliability for industrial electronics. It provides critical selection data on anti-corrosion (Zinc-Nickel, Dacromet), electrical function (Silver, Nickel, Tin), mechanical hardness (Nitriding/QPQ), and dimensional precision (Electroless Nickel). The guide helps engineers match the optimal coating to extreme environments, high-current, and strict dimensional needs.

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Oct 25,2025

Vifort transforms custom and non-standard nut production from machining to cold forging, achieving higher efficiency, lower costs, and stronger performance for large-scale manufacturing.

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

Sep 29,2025

Screws made of 6061-T6 aluminum alloy are widely used in aerospace, automotive, marine, sports equipment, and electronics industries due to their high strength, lightweight, and excellent corrosion resistance. As a factory manufacturer, we specialize in custom production according to customer drawings and samples, with options for anodizing, surface finishing, and bulk supply.