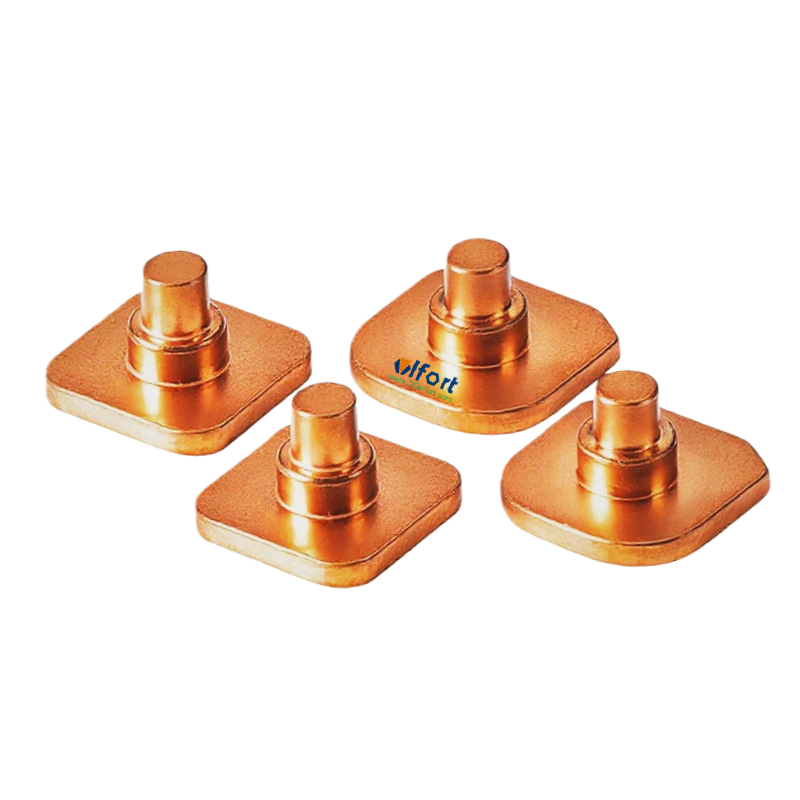

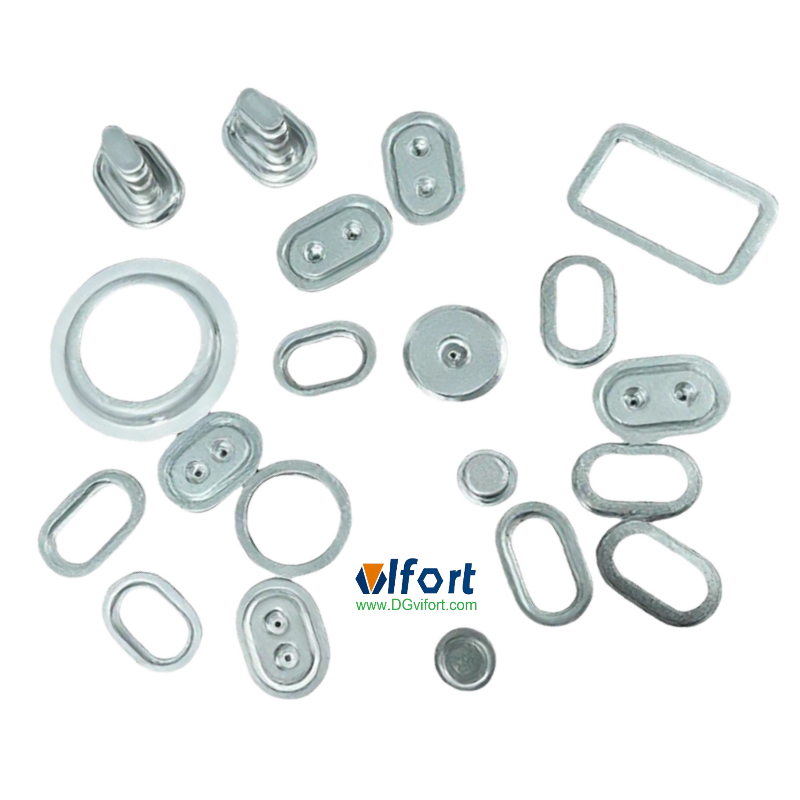

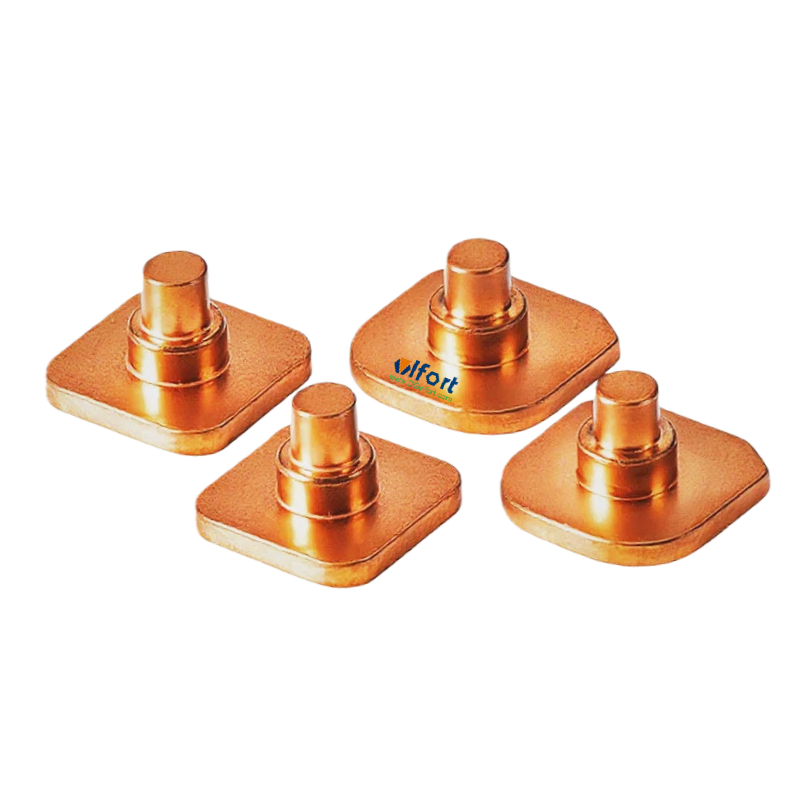

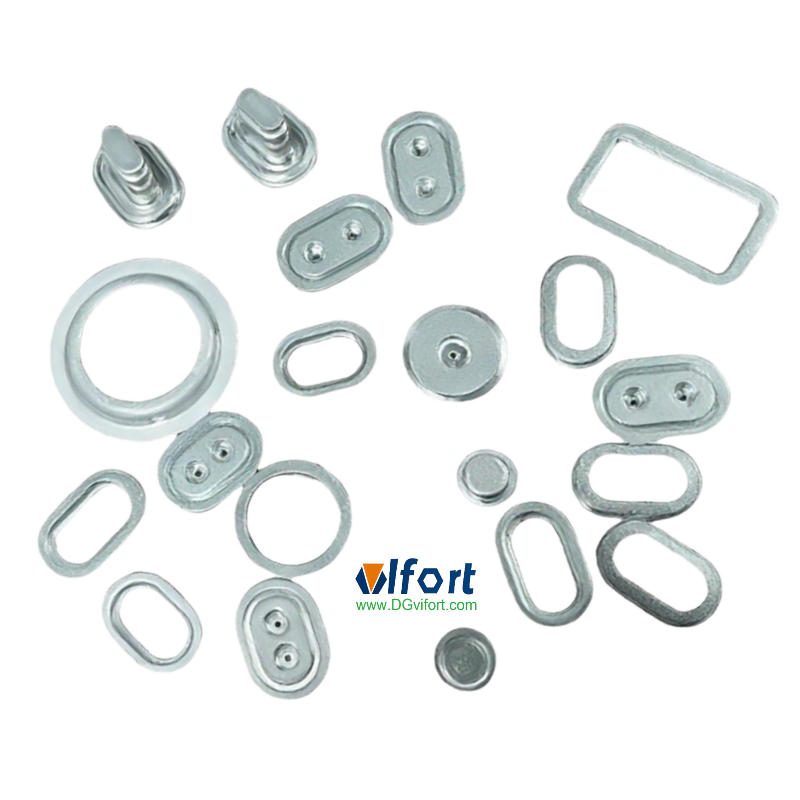

Precision Micro Metal Stamping Parts

Precision Micro Metal Stamping Parts

Product Overview

Our precision micro metal stamping parts are designed for applications that require tight tolerances, miniature dimensions, and stable high volume production. With more than twenty years of experience in Japanese precision tooling, we manufacture complex metal components with accuracy up to ±0.02 mm and excellent consistency.

Key Features

High precision manufacturing with ultra stable dimensional tolerance

Suitable for miniature, thin wall, and complex structures

High speed progressive stamping capability

Daily output per mold up to 300000 pieces

Material utilization above 80 percent through our proprietary dual strip feeding system

Consistent quality for long term mass production

Manufacturing Capabilities

Precision stamping

High speed progressive stamping

Cold forging and cold extrusion

Deep drawing for thin wall and deep cavity structures

In die tapping

In die riveting

In die forming

Multi step compound processing for complex geometries

Material Options

Kovar and Fe Ni Co alloy

Fe Ni alloy

Hermetic sealing alloys

Beryllium copper

Oxygen free copper

Red copper and brass

Stainless steel 301 304 316 430

Molybdenum copper

Tungsten copper

These materials support demanding applications in semiconductors, sensors, communication modules, and electronic connectors.

Typical Applications

Semiconductor device components

Optical communication metal housings

Sensor package components

Precision connector and terminal parts

Micro electronic structural parts

Hermetic sealing metal parts

Why Choose Us

Two senior tooling designers with Japanese precision factory background

Five experienced progressive die engineers

Patented dual strip precision feeding system

Strong capability in special alloys and micro components

High efficiency, stable quality, and competitive cost control

Custom Production

We support complete customization based on customer drawings and samples.

We accept PDF, DWG, STEP and sample based development.

Dimensional tolerance, surface treatment, and material specifications can be fully customized.

RFQ and Drawing Based Quotation

We provide fast quotation services based on customer drawings.

Send your drawing or sample and we will provide a detailed quotation including tooling plan, lead time, unit price, and batch production options.