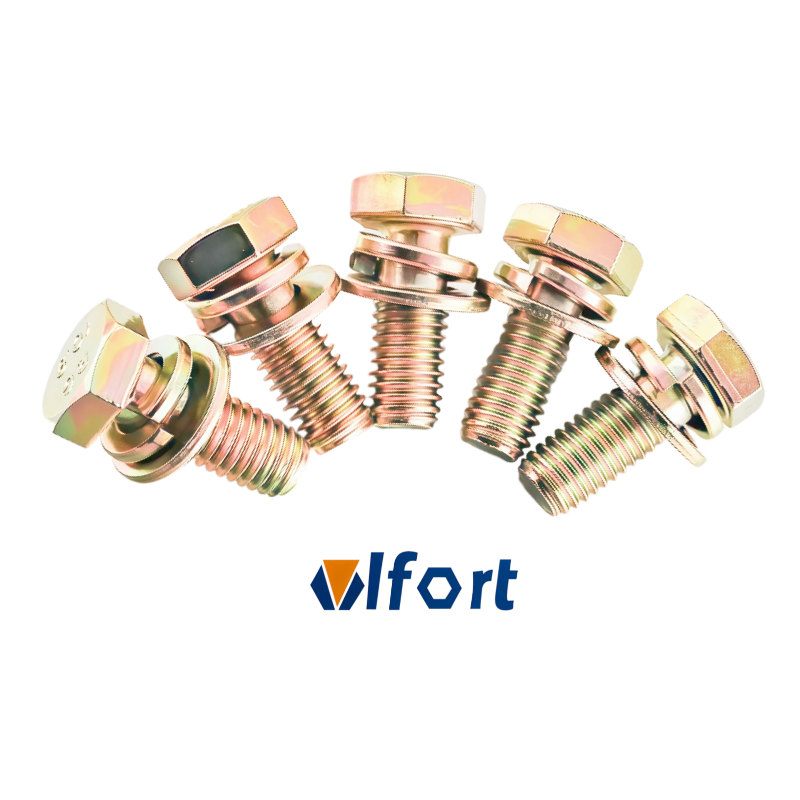

High-Performance SEMS Screws | Pre-Assembled Screw and Washer Assemblies

SEMS Screws: The Ultimate All-in-One Fastening Solution to Accelerate Your Assembly and Enhance Product Reliability

Key Features & Benefits at a Glance

Drastically Increase Assembly Speed: By combining two components into one, you eliminate the manual step of placing a washer, saving valuable time in both manual and automated assembly.

Eliminate Dropped & Lost Washers: The captive washer design ensures the washer is always present and correctly oriented, preventing costly mistakes and component loss on the factory floor.

Enhance Connection Reliability: Our SEMS screw assemblies ensure proper load distribution, protect component surfaces from damage, and provide superior resistance to loosening caused by vibration, especially when using lock washers.

Simplify Inventory & Logistics: Reduce your Bill of Materials (BOM) complexity and lower inventory costs by managing a single Stock Keeping Unit (SKU) instead of two separate parts.

Ideal for Automation: The consistent, all-in-one design is perfect for automated feed systems, enabling smoother, faster, and more reliable production runs.

Versatile Combinations: Available with a wide variety of screw and washer types to meet the exact needs of your application.

Unlock Unmatched Functionality and Convenience

In today's competitive manufacturing environment, every second and every component counts. Our pre-assembled screw and washer assemblies are designed to give you a competitive edge by tackling common production challenges head-on.

1. Streamlined Production FlowThe single greatest advantage of a SEMS screw is the efficiency it brings to your workflow. Imagine an operator who no longer has to reach for a screw and then a washer. This simple change reduces motion, minimizes the chance of error, and multiplies time savings across thousands of installations. This makes SEMS screws the fastener of choice for high-volume industries like electronics, automotive, and appliance manufacturing.

2. Engineered for Superior PerformanceFunctionality is at the core of our design. A properly selected washer is critical for the integrity of any bolted joint. Our SEMS screws guarantee that the correct washer is used every time.

Flat Washers distribute clamping force over a wider surface area, preventing damage to soft materials like plastic or aluminum.

Spring & Lock Washers (e.g., Helical, Conical, Tooth Lock) create tension and bite, providing excellent anti-vibration properties to ensure your connection remains secure over time.

Wide Range of Applications

Our versatile screw and washer assemblies are trusted by engineers and manufacturers in a variety of industries:

Electronics: Securing printed circuit boards (PCBs), chassis, and connectors.

Automotive: Interior components, engine bay assemblies, and electronic modules.

Appliances: Manufacturing of washing machines, refrigerators, and other white goods.

Telecommunications: Assembling server racks, networking equipment, and enclosures.

General Machinery & Manufacturing: Anywhere a reliable and efficient fastened joint is required.

Your Design, Our Expertise: Free Samples & Custom Manufacturing

We understand that standard parts don't always fit unique designs. That's why we offer comprehensive customization and risk-free testing.

1. FREE SAMPLES FOR EVALUATIONWe are confident in the quality and performance of our fasteners. Contact us to request free samples for your prototyping and pre-production testing. See the difference a SEMS screw can make in your assembly process firsthand.

2. CUSTOM MANUFACTURING TO YOUR SPECIFICATIONSHave a specific requirement? We specialize in custom manufacturing from your technical drawings or specifications (来图定制). Our engineering team will partner with you to develop the perfect SEMS screw solution.

Customizable options include:

Head Style: Pan, Hex, Truss, Flat, Round, etc.

Drive Type: Phillips, Torx®, Hex Socket, Slotted, etc.

Material: Steel (various grades), Stainless Steel, Brass, Aluminum.

Finishing/Plating: Zinc, Nickel, Black Oxide, Passivated, and more.

Washer Type: Flat, Spring Lock, External/Internal Tooth Lock, Conical, Wave, and more.

Threads & Dimensions: Metric or Imperial sizes tailored to your needs.

Technical Specifications

| Attribute | Specification Options |

| Screw Material | Carbon Steel, Stainless Steel (304, 316), Brass |

| Washer Material | Carbon Steel, Stainless Steel |

| Diameter Range | M2 - M12 (or Imperial equivalent) |

| Length Range | 4mm - 150mm (or Imperial equivalent) |

| Head Types | e.g., Pan, Hex Flange, Flat, Truss, Round Washer Head |

| Drive Types | e.g., Phillips, Pozi, Torx®, Slotted, Hex Socket, Combo |

| Washer Types | e.g., Flat, Split Lock, External Tooth, Internal Tooth, Conical |

| Plating & Finishes | e.g., Zinc Plated (Clear, Yellow, Black), Nickel, Black Oxide |

| Standards | ISO, DIN, ANSI, JIS, or Custom |

Get Your Custom Fastening Solution Today!

Ready to reduce assembly time, lower costs, and improve your product's reliability? Contact our expert team now.